Categories

Contact Us

E-mail :

sales@loyicn.com

Phone/WhatsApp:

+86-15089190217

Address:

2110, Building 2, 1st HaGongDa Road,TangJiaWan Town, GaoXin District, Zhuhai,Guangdong 519085

Timing belt APL coating machine for belt width 100 mm

- Commodity name: Timing belt APL coating machine for belt width 100 mm

- Product Details

-

Timing belt APL coating machine for belt width 100 mm

Features & Benefits1.Water circulation system with stainless water tank, long time to keep water cooling for timing belt running wheel. The timing belt wheel will not overheat and belt will not stick to timing wheel. Make sure 24 hours no-stop working for large quantity coating.2.With 5pcs timing belt wheels (belt type optional) Can change timing belt wheels to suit different timing belts and improve coating accuracy.3.The cylinder controls the welding gap between the timing belt and the material and the distance can be adjusted. The total thickness of welding can be adjusted, not too thick or too thin. To match usage requirements4.Switzerland "BAK" brand heating gun Ensure the coating quality and speedIn the world of industrial machinery and manufacturing, a new breakthrough has emerged with the introduction of the state - of - the - art Timing Belt APL Coating Machine.

The Timing Belt APL Coating Machine is a game - changer in the production of timing belts. It is engineered with precision and advanced technology to provide an efficient and high - quality coating process. This machine is designed to apply APL (Advanced Polymer Layer) coatings onto timing belts with utmost accuracy.

One of the remarkable features of this coating machine is its ability to ensure a uniform and consistent coating thickness. This is crucial as it directly impacts the performance and durability of the timing belts. The precise coating application helps in reducing friction, enhancing the belt's power transmission efficiency, and increasing its overall lifespan.

Manufacturers using the Timing Belt APL Coating Machine have reported significant improvements in their production processes. The machine is equipped with an intelligent control system that allows for easy adjustment of coating parameters according to different belt specifications. This not only saves time during setup but also reduces waste of coating materials, leading to cost - savings.

Moreover, the Timing Belt APL Coating Machine is designed for high - speed operation, enabling manufacturers to increase their production output without compromising on quality. It has a robust construction that can withstand continuous operation in industrial environments, ensuring minimal downtime.

In terms of environmental impact, the machine is engineered to minimize emissions and waste. The APL coating process is optimized to use the least amount of chemicals while still achieving excellent coating results, making it an environmentally friendly option for timing belt manufacturers.

The introduction of the Timing Belt APL Coating Machine is set to have a far - reaching impact on various industries that rely on timing belts, such as automotive, manufacturing, and robotics. It represents a significant step forward in the production of high - performance timing belts, and industry experts predict that it will soon become an essential piece of equipment in belt manufacturing facilities around the world.

LOYICN product code : LYTN100

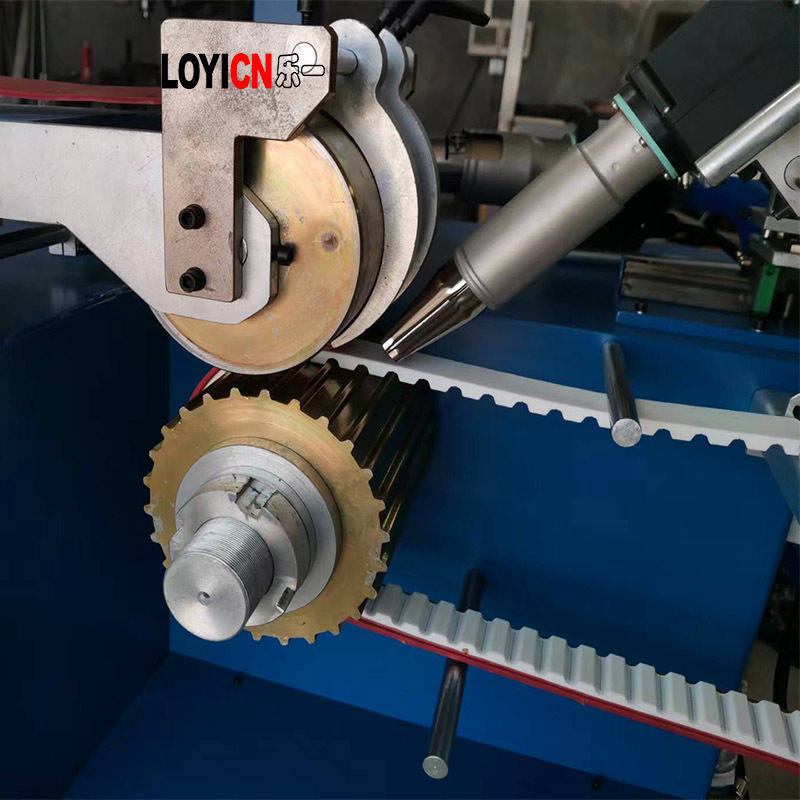

1. Control panel: control roller fixture, heat gun heating, water circulation cooling etc.2. Cylinder: control roller fixture route3. BAK brand heating gun produced in Switzerland4. Synchronous drive wheel: matching timing belt tooth, equipped with water circulationcooling5. Stainless steel water tank for water circulation system6. Timing belt standDescription:This machine is mainly for coating material (APL, PU, form and etc.) on PU timing belt by hot air gun to soften and protect timing belt.Machine Videos: https://youtu.be/Q0GhocEgTgcOptional Function: Adding guide on the timing belt

1. Control panel: control roller fixture, heat gun heating, water circulation cooling etc.2. Cylinder: control roller fixture route3. BAK brand heating gun produced in Switzerland4. Synchronous drive wheel: matching timing belt tooth, equipped with water circulationcooling5. Stainless steel water tank for water circulation system6. Timing belt standDescription:This machine is mainly for coating material (APL, PU, form and etc.) on PU timing belt by hot air gun to soften and protect timing belt.Machine Videos: https://youtu.be/Q0GhocEgTgcOptional Function: Adding guide on the timing belt

LOYICN Timing belt APL coating machine specification :

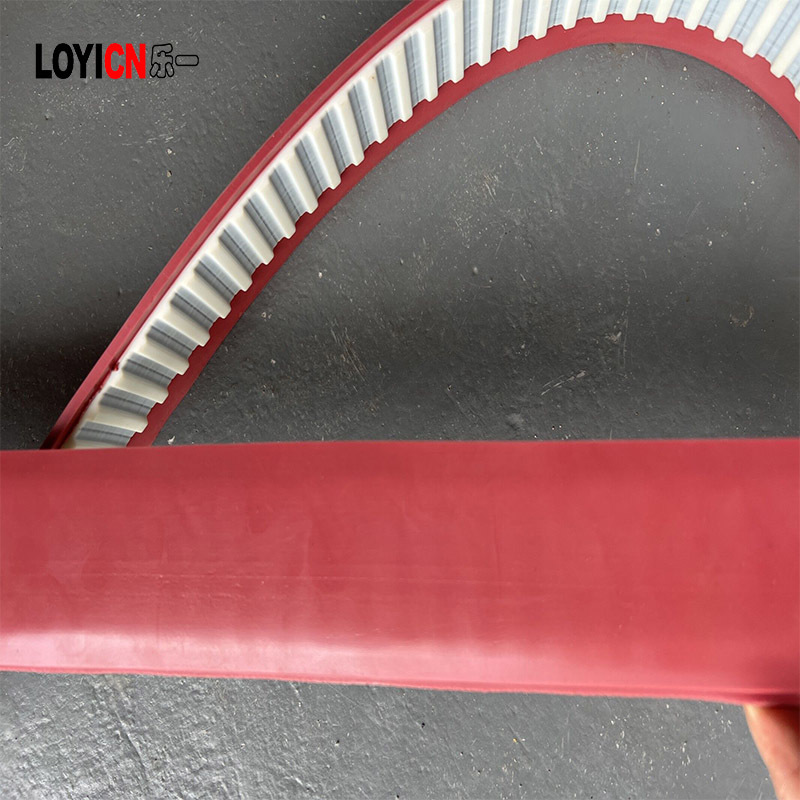

Difference colour avaiable

PU timing belt affix coating machine

affix coating machine

Export package:

◆ Our Services:

1. For all your inquiries about us or our products, we will replay you in detail within 24 hours.

2. We own well- trained and passional sales & after-sale services who can speak English language.

3. We offer OEM services. Can print your own logo on product, can customize the retail box packing and other things.

4.We have very experienced R&D engineers, and we have strong ability to do ODM service.

Welcome to your inquiry!

Kindly let me know if you need any further assistance.

ZHUHAI LOYICN MACHINERY CO., LTD

——————————————————

M/WhatsApp: 86-15089190217

E-mail: sales@loyicn.com

Keywords:

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products

Grinding a Curved Groove on Timing Belt with LOYICN Cross Cuting Grinding Machine This milling machine can automatically mill horizontal teeth on the timing belt for making timing belt backside groove, DB and DA timing belt.

In the industrial manufacturing sector, a new star has emerged - the cleats welding machine for timing belt.This innovative machine is designed to meet the specific and often complex demands of welding cleats onto timing belts.

Quality, Honesty, Service and Innovation are the LOYICN core values.In the industrial world, especially in the realm of conveyor systems, a heavy duty belt slitter for rubber conveyor belt is an indispensable tool.